Complete range of SMT line machinery

Here you get the complete range of SMT line machinery for SMT production lines

Through expert guidance we ensure you get the SMT line-up that fit your production needs.

Laser Marker

PCB laser marking | Nutek laser mark your PCB with a barcode, UPC-A, DataMatric, QR code, code 128 or code 39 for perfect traceability.

Screen Printer

Solder paste screen printer | Solder paste printing on PCB with speedy YAMAHA screen printers. See our solder printing machinery.

Dispenser

Solder paste & glue dispensing | Dispensing solder paste & glue with high accuracy, great efficiency and high speed. See our YAMAHA dispenser.

We offer you the full overview of all SMT line machine categories for the complete SMT production line. Need help to find a machine?

CORE-emt is the proud exclusive sole supplier of YAMAHA SMT machinery and BTU reflow ovens for OEM & EMS factory's in Scandinavia.

To make your SMT production line complete we also have a wide range conveyor board handling and laser markers.

Pick & Place

Surface mounting on PCB's | SMT line component placement systems at it’s best. See YAMAHA's Pick & Place machines, feeders types and mounting heads.

Inspection

AOI, X-ray & SPI inspection | SMT inspection; AOI, X-ray and SPI is essential in a SMT production line to ensure high quality.

SMT line guidance

We are here to help & guide you | Finding the right assembly line machinery is important to get a smooth running SMT line. We can help you get the best line setup.

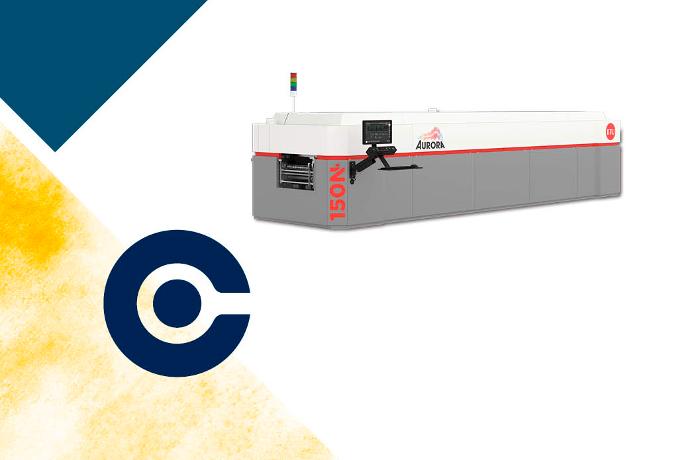

Soldering solutions

Inline SMD soldering | Reflow soldering, wave soldering and an inline soldering robot in your SMT production line-up will ensure high productivity.

Board Handling

Bring your boards from A to B | Prime conveyor PCB board handling; Loader, unloader, buffer, transport and traffic control from Nutek.

SMT line software

PCB assembly production software | See the YAMAHA YsUP software packages for programming, Setup, Monitoring, Traceability, M2M solutions and maintenance.