Accelerate mounter and AOI program creation with Yamaha's program generator

Faster, smarter & easier new product introduction with Yamaha's program generator

Yamaha’s latest software update makes new product introduction even faster and more efficient. The enhanced Yamaha YSUP-PG program generator is designed for Yamaha’s surface mounters and inspection systems - helping you streamline setup, improve accuracy and reduce manual work.

With a refreshed interface and new automation features, YSUP-PG now accelerates data conversion from popular EDA file types such as ODB++. The software takes care of routine steps, provides clickable task lists and updates component-placement images in real-time, giving engineers a clear overview of progress and helping them focus on quality instead of repetitive work.

By handling more of the setup automatically, YSUP-PG lets users apply their expertise where it matters most - ensuring data integrity and generating high-quality mounter and inspection programs faster than ever.

Simultaneously mounter and AOI program creation

A key new feature is that AOI libraries can now be generated directly from CAD data. This means your team can develop mounter and AOI programs at the same time, boosting efficiency and shortening NPI lead times.

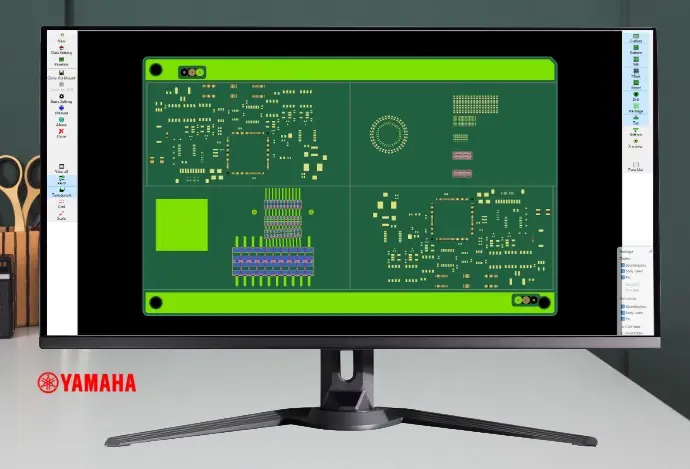

YSUP-PG also includes improved Gerber image and CAM conversion tools, producing highly accurate simulated board images to simplify AOI programming. The Gerber image tool automatically combines layer descriptions to construct detailed PCB images - no manual setup required.

Digital pin positioning and accurate trial mounting simulation

Combining Gerber and CAD data, Yamaha YSUP-PG calculates push-up pin positions digitally, removing the need for manual fine-tuning on physical assemblies. This not only saves time but also helps ensure a smoother transition from prototype to production.

Engineers can even run desktop trial mounting, verifying component coordinates, polarity and angle in advance - so full production can start right away with confidence.

Caption: The YSUP-PG CAM converter generates highly detailed simulated board images.

Accelerate mounter and AOI program creation with Yamaha's program generator