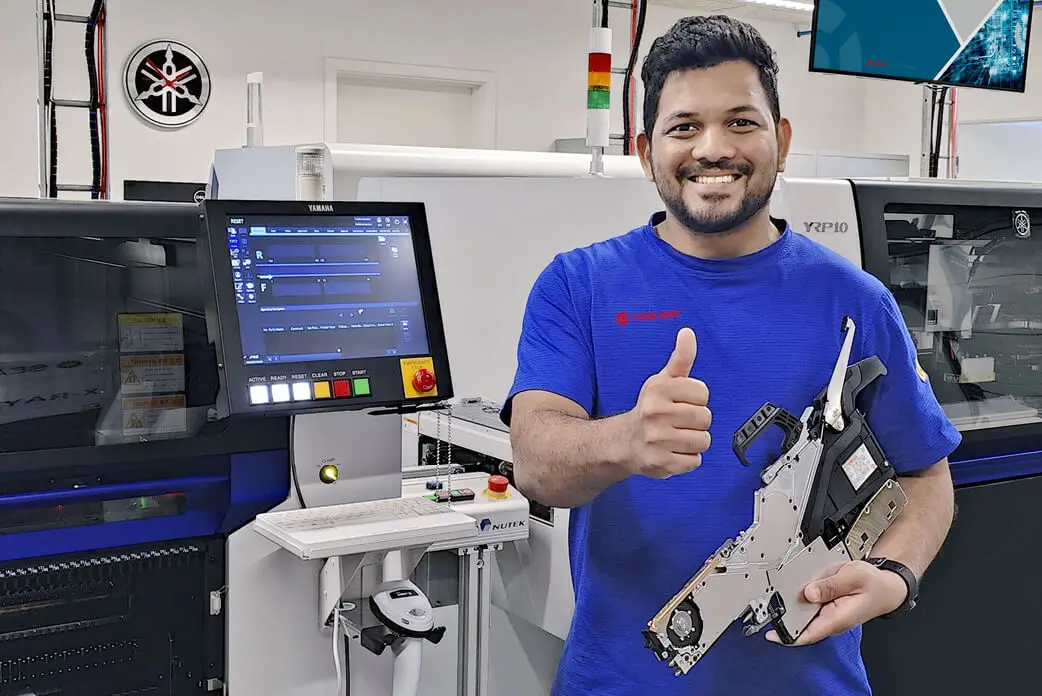

Feeder repair service

Inspection, calibration & repair of Yamaha feeders

Send your feeders to our inhouse repair center with confidence

Each Yamaha feeder

undergoes

A complete inspection

A precise calibration

An optional* repair if needed

* before parts replacement you will be provided with spare parts price for approval, prior to any repair work.

If any damaged or worn parts are found, we’ll send you a quotation for approval before carrying out the repair.

Once approved, we replace the necessary parts, finalize the calibration, and prepare the feeders for safe return.

With every repaired feeder, you’ll receive a calibration report and a summary of any replaced parts, giving you full transparency and traceability.

Book a feeder repair service - or get more info

Get in contact to book by phone, mail or leave a message

Why regular feeder repair service make a difference

Choosing professional feeder maintenance and repair isn’t just about fixing what’s broken - it’s about keeping your SMT line running smoothly and efficiently.

Here’s what you gain when CORE-emt takes care of your feeders:

- Longer feeder lifespan through regular, expert maintenance

- Increased uptime - fewer unexpected feeder issues mean fewer production line stops

- More stable production with fewer mis-picks & less component waste

- Improved product quality from consistently calibrated feeders

- Lower operating costs thanks to reduced component loss and breakdowns

- No need to invest in maintenance tools or train in-house repair staff

- Full transparency - get clear insight into feeder status and service history

- Less operator intervention - and more focus on production

- Optimized performance from every feeder on the line

Let us handle the maintenance - so you can focus on output.

We service and repair the following types of feeders

We offer service, calibration and repair on the following feeders:

- Yamaha ZS feeder

- Yamaha ZSR feeder

- Yamaha SS feeder

- Yamaha ALF auto load feeder