PCB rework - precision and temperature control is everything

The challenge? Applying heat only where it is needed - without affecting sensitive components nearby.

PCB rework precision heat where you need it

Hot air soldering enables cool results:

- gentle and focused PCB rework

- at the lowest possible temperature

- ensuring no impact on the surrounding area.

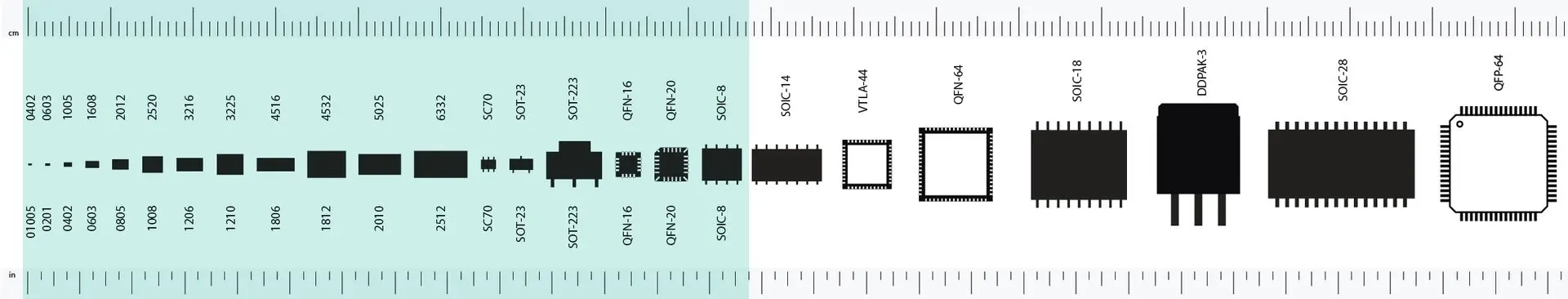

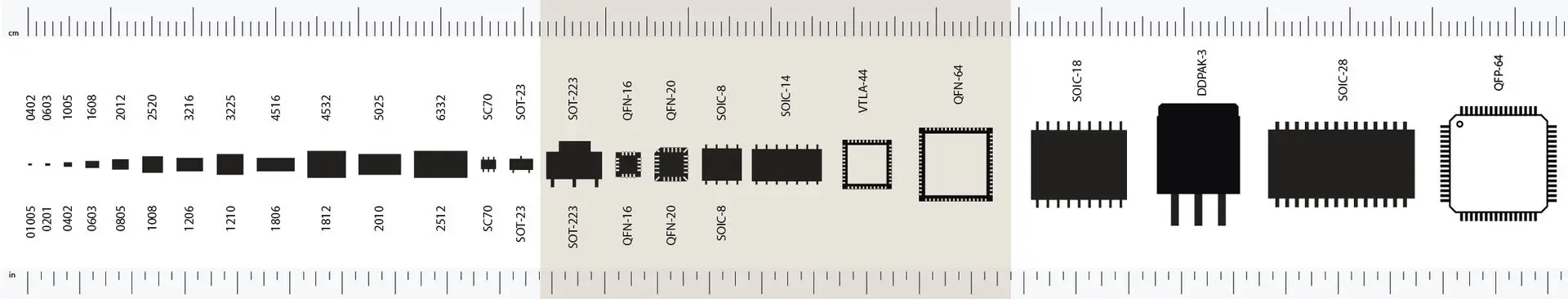

JBC hot air tools let you rework all types of SMDs quickly and safely – including even the largest QFPs and PLCCs.

For optimal protection of specific areas or nearby components, we recommend using protecting extractors when desoldering medium to large SMD's. They focus the heat precisely where needed, as shown on the video.

NH hose set

The NH is the ideal tool for precise and safe SMD rework – even for components as small as 01005".

Designed for full control under the magnifying glass, it delivers reliable results without disturbing nearby components.

TET hose set

The TET Precision Heater Hose Set enables fast and safe rework of small and medium-sized SMDs.

For optimal protection of specific areas or nearby components, we recommend using Protectors or Extractors. To focus the heat precisely where needed.

NH hose set

The JTT Heater Hose Set makes it easy to rework medium and large SMDs quickly and safely – including even the largest QFPs and PLCCs.

For added protection of specific areas or nearby components, we recommend using Protectors and Extractors. To direct heat precisely where needed.

Safe & easy desoldering with extractor

Using JBC hot air soldering technology

-

Positioning

Choose the extractor which best fits the SMD you need to desolder. Activate the suction pump and push the extractor onto the component. - Heating

While you apply heat to the component, the surrounding elements are protected. - Extracting

Automatic withdrawal of the desoldered component.

Your PCB rework starts here

Dive into our JBC soldering tools, browse JBC catalogues and get personal guidance for safe and precise hot air desoldering.

Find your desoldering tools >

PCB rework - precision and temperature control is everything