Yamaha SMT Traceability package

Traceability in a modern electronics production

Yamaha YsUP software

Yamaha SMT Traceability package

Performing traceability in your SMT production requires that production data are captured to perform the adequate SMT traceability that is needed in a modern electronics factory.

The YAMAHA YsUP Traceability software is a part of YAMAHA SMT's new software platform.

Search in production history

An effective traceability tool captures real-time data based on to your PCB assembly line(s) and other machine-driven events.

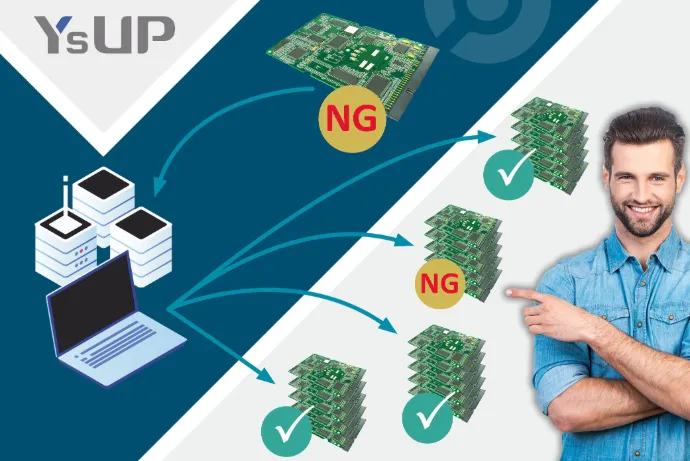

Product history search flow:

- NG failure occurs

- Check for faulty lots in database based on NG failure

- Lots in which there are placed faulty components are found

Searching in production history will enable you to request that specific serialized data are located to pinpoint information at component level, to gain more visible traceability to extensive relational data.

A powerful tool to analyse component mounting quality throughout production

We call it ‘all image tracer’ as it saves all your mounters component recognition images – with no tact loss - while production runs.

You can easily search for the specific image in the ‘all image tracer’ database, to swiftly pinpoint causes of defects due to ‘N-point verification’ linking.

Comparing the mounter component recognition images with Screen Printer and AOI images (before and after reflow soldering) will support pinpointing cause of defect.

Questions about the YsUP traceability package

We assist you personally with prices and more information