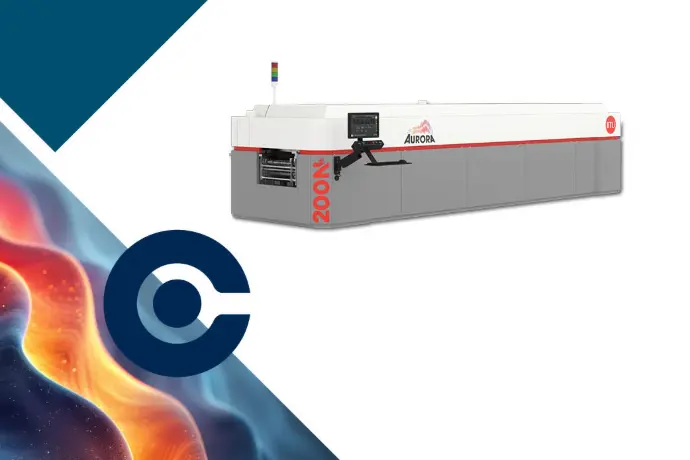

Aurora - reflow soldering in a greener light

The new reflow platform designed for top performance, a sustainable solution engineered for reflow excellence

Reflow sustainability

Are you ready to meet the greener demands of tomorrow?

BTU International knows that sustainability and operational efficiency go hand in hand. BTU’s new reflow oven platform Aurora has been designed not only to reduce environmental impact but also to deliver exceptional performance while lowering the overall cost of ownership.

With state-of-the-art features, this system is the perfect solution for manufacturers looking to optimize production while contributing to a greener future.

Key features for a greener

&

more efficient soldering process

Lower gas

& power consumption

BTU’s reflow oven is designed with advanced gas management capabilities, drastically reducing nitrogen consumption through efficient recycling.

Along with Energy Pilot, which minimizes power usage during non-production times, and Smart Power technology that reduces peak power demand at startup, you’ll experience significant energy savings without sacrificing performance.

Aqua Scrub Flux management technology

BTU’s innovative Aqua Scrub Flux management technology enhances the reflow process by reducing cost of ownership and minimizing maintenance.

This aqueous scrubber system efficiently handles flux with >90% removal efficiency, eliminating the need for heat exchangers or filters to be cleaned or replaced.

It also ensures a consistent thermal profile and limits exposure to personnel, creating a safer and cleaner working environment.

Reflow soldering in a greener light

Efficiency & lower cost of ownership with Aurora reflow soldering

- Reduced cost of ownership: Lower energy and gas consumption, combined with less maintenance and fewer parts to replace, makes the Aurora reflow oven a cost-effective solution for the long term.

- Efficient use of manufacturing floorspace: Auroras compact design allows you to make the most of your production area, maximizing output without occupying excessive space.

- Significant reduction in maintenance / downtime: With fewer moving parts and no need for heat exchangers or filters to maintain, the Aurora reflow oven reduces downtime, ensuring increased equipment longevity and less frequent parts replacement.

- Increased uptime: The oven’s robust design and reliability ensure that you can keep your production running smoothly with minimal interruptions.

- High-Efficiency flux extraction: Auroras advanced flux extraction system maintains a consistent thermal profile, contributing to superior process repeatability and product quality.

- Hands-off approach: The fully automated system requires minimal user intervention, limiting flux exposure to personnel and reducing the need for manual handling.

Reflow innovation

Innovative reflow technology at its core

- Aqueous scrubber technology: BTU’s innovative oven scrubber system works with most flux chemistries, providing a flexible solution for your reflow soldering needs.

The efficient aqueous-based process not only supports high throughput but also ensures end-to-end serviceability access, making maintenance easier and quicker. - Fully automatic process: Auroras reflow system is designed to function with minimal user intervention, making it highly efficient and easy to integrate into any production line.

With its innovative features and focus on sustainability, the reflow oven provides the perfect balance of environmental responsibility and operational efficiency.

Whether you’re aiming to reduce energy consumption, cut costs, or enhance the longevity of your equipment, the Aurora solution is designed to meet your needs - and help you take a greener step into the future of manufacturing.

Experience the future of greener reflow soldering with Aurora - where innovation meets sustainability!

Aurora - reflow soldering in a greener light