Discover the new BTU Aurora series - the ultimate reflow soldering ovens for any SMT line

Electronics manufacturers, gear up for next level in SMT reflow soldering with the cutting-edge BTU Aurora.

Built on the robust BTU Pyramax platform, the Aurora elevates innovation, boasting enhanced features that redefine reflow dynamics.

Technical Edge: Why pick the BTU Aurora reflow oven?

Minimal user maintenance

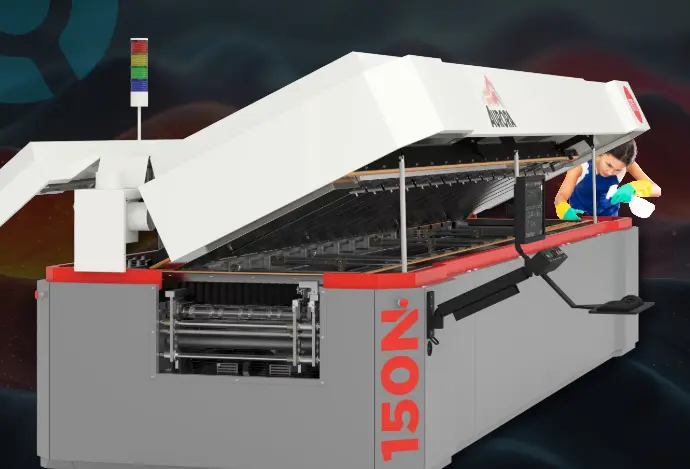

Aurora reflow ovens have a fully accessible process chamber that ease and speed up maintenance performed by the oven operator.

Improved flux removal technology in the process chamber, called Aqua Scrub. It is a water-based scrubbing solution that cleans the reflow chamber with a 90% or higher flux removal efficiency.

Unmatched thermal uniformity

With the new Aurora platform, BTU reaffirms their superiority in convection heating.

All Aurora reflow oven users benefit from the exceptional soldering

flexibility and unmatched process control.

Lowest ownership cost

The Aurora reflow oven is designed and built to keep user costs low with upgraded energy- and time-saving features such as:

- Power savings

- Less nitrogen usage

- Timesaving improved maintenance access

- Reduced oven contamination

Cost saving reflow oven

Aurora - the ultimate cost-saving reflow oven solution

BTU's latest reflow oven platform, Aurora, has been revamped with a clear goal: providing the most economical ownership experience in the industry.

As a result, Aurora reflow ovens offer:

- SmartPower software cuts down on electricity bills by reducing peak power usage, enabling lower connected loads

- SmartPower software enables rapid start-up and re-heat times using less power

- EnergyPilot software automatically lowers operating costs by taking advantage of idle periods e.g. turning off heaters, coolers, and blowers to save energy.

The SmartPower & EnergyPilot software is included in the Aurora Wincon control system as standard software tools.

Easy maintenance

Aurora reflow ovens make operator maintenance easy

The fully accessible oven chamber makes maintenance for operators easy, and thereby reduces downtime associated with maintenance.

Smart maintenance software enables customizable maintenance reminders and log that keeps track of all activity.

If your SMT production line is running high-volume PCB production, that require maintenance more frequently - or your board production require a minimum of flux contamination, we recommend that you add our patented reflow oven flux management, AquaScrub, so you can enjoy 90% flux removal efficiency with no condensers to clean.

With AquaScrub cleaning system is integrated within the Aurora oven, and runs automatically while production is running.

It runs with a water-based scrubbing solution that ensures simple waste management with little to no exposure to captured flux solution.

A reflow powerhouse

The reflow oven taking the thermal precision lead; meet Aurora

Here's what makes the Aurora special

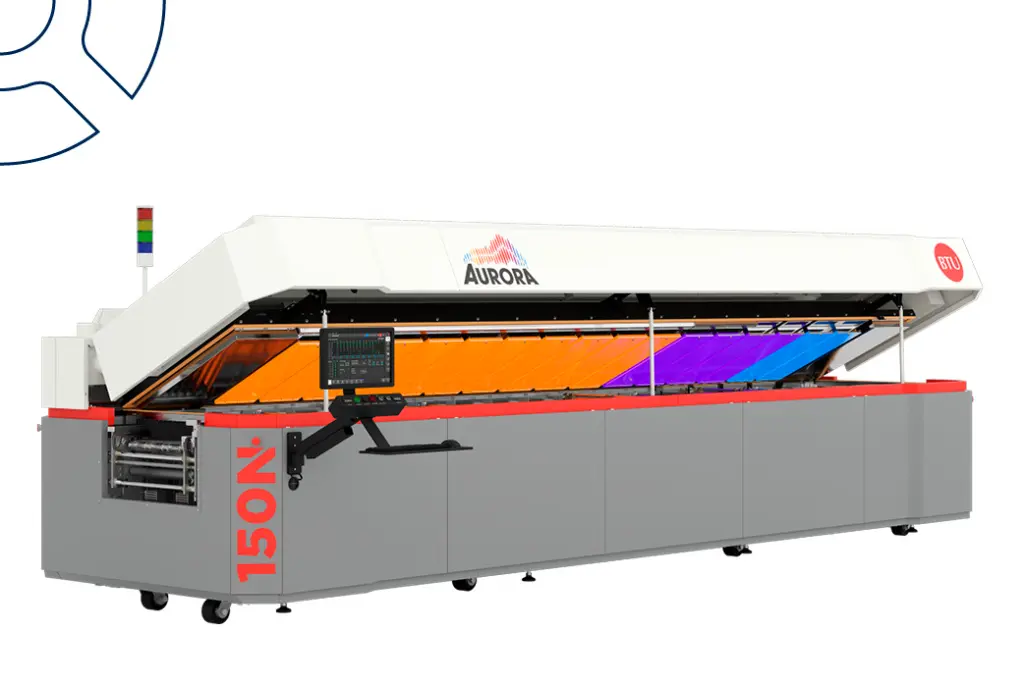

The Aurora reflow platform stands out with its innovative feature that lets you customize a flexible (depicted in purple) heating and cooling zones right when you place your order. This flexibility means you can fine-tune the cooling ramp rates or boost throughput for lighter products, all within the same compact footprint of the original Aurora design.

Superior reflow performance

The Aurora reflow oven boasts a programmable reflow blower pressure range of 0.5-1.5 IWC in combination with unmatched uniform static pressure* from an efficient reflow gradient, giving your reflow soldering process unparalleled repeatability, flexibility and thermal uniformity in each independent heating and cooling zone.

* The Aurora series achieves superior temperature control, uniformity, and heat transfer to boards by regulating heating through static pressure rather than just changing blower speed.

The open Aurora reflow oven shows the:

- heating zones with orange color

- flexible zones that are customizable to either heating or cooling in purple color

- cooling zones with blue color

BTU Aurora range

Have a look at all the Aurora reflow oven models that effortlessly can tackle critical soldering process or productivity challenges, optimizing your reflow soldering like never before.

Out-of-this-world soldering - literally

BTU reflow ovens are being used in the production of electronics for space missions. So, the next time you look up at the night skies, remember that BTU’s technology might have helped put some of those satellites and spacecraft up there.

Aurora advantages

Let us guide you through the unparalleled thermal precision and efficiency Aurora will bring to your reflow processes.

Discover with us how Aurora can enhance your productivity and reduce costs.

Discover the new BTU Aurora series - the ultimate reflow soldering ovens for any SMT line