New Yamaha pick & place options

Enhance SMT line capabilities with Yamaha Pick and Place upgrades

Looking to elevate your SMT production? Yamaha Robotics has rolled out three exciting hardware-based upgrades for Yamaha YR mounters, designed to boost your line’s speed, accuracy, and flexibility. These upgrades are easy to integrate and are perfect for industries like automotive, aerospace, medical, lighting, and other high-demand sectors where precision is key.

Whether you're working on PCB assembly for vehicles, medical devices, wind energy or other advanced industries, these enhancements will help you achieve superior quality and increased efficiency in your production process.

Enhance SMT line capabilities

Enhance SMT line capabilities by improved first-pass quality control

Feeder errors, incorrect reels, and defective components are common challenges in high-volume SMT production. Yamaha’s LCR verification system takes quality control to the next level by measuring LCR; inductance, capacitance, and resistance values of SMD components before placement.

This ensures that only the correct parts, with the right tolerances, are placed onto the PCB - drastically reducing rework and boosting first-pass control. Compatible with Yamaha YRM mounters as well as Yamaha YSM pick & place, this feature integrates seamlessly without requiring additional software or hardware modifications.

Enhance SMT line capabilities

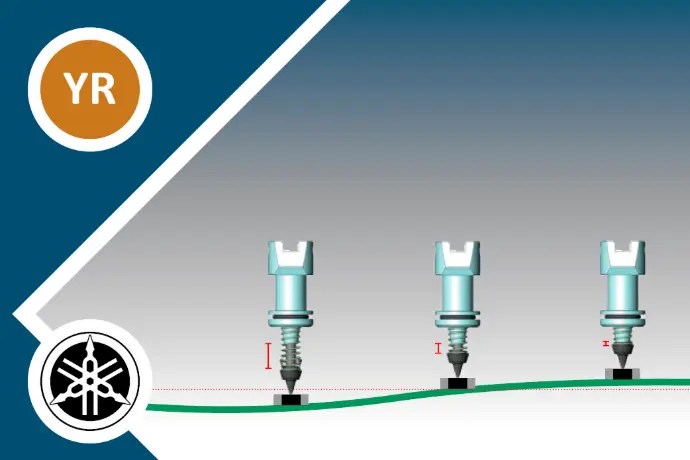

Nozzle-tip force measurement for higher precision placement

Ensuring precise component placement is key to maintaining high SMT production quality. Yamaha’s nozzle-tip force measurement system detects early issues like blockages, allowing for quick maintenance. Installed at the mounter’s feeder interface, it offers a menu-driven setup and measures placement force down to 0.1N resolution.

By implementing nozzle force monitoring, manufacturers can reduce errors, minimize downtime, and maintain first-pass control, ensuring stable and reliable SMT line performance. This feature is available for all Yamaha YRM mounters.

Enhance SMT line capabilities

Handle larger PCBs with ease: Large board option for complex assemblies

For manufacturers working with large PCB assembly, Yamaha’s new large board handling upgrade allows YRM mounters to process boards up to 1.5 meters long and 510 mm wide. This expands production capabilities by more than 30% compared to standard YRM mounters.

This upgrade is ideal for LED lighting boards, high-power electronics and IMS (Insulated Metal Substrate) assemblies. Supporting board thickness up to 10 mm and weights up to 10 kg, this feature enables high thermal capacity component placement on materials like heavy-gauge copper or aluminum IMS.

Want to enhance SMT line capabilities?

Want to enhance your pick and place machine capabilities? Discover how Yamaha YR mounters can improve your PCB assembly efficiency.

Contact us today for expert insights and upgrade recommendations

Seamless SMT Integration with Yamaha SMT

The future of PCB assembly starts with Yamaha – here’s why

Each of these upgrades can be implemented individually or together, providing a customizable path to improved efficiency and quality. As part of Yamaha’s full SMT line solutions, these enhancements integrate seamlessly with the:

- YRP printers for precise solder paste application

- YRM-D dispensers for automated adhesive and coating application

- YRM mounters for high-speed, high-accuracy pick and place

- YRi-V inspection systems for advanced optical inspection

For SMT manufacturers looking to stay ahead of production challenges, these Yamaha YR mounter upgrades offer a smarter, more flexible, and future-proofed solution.

Enhance SMT line capabilities with Yamaha Pick and Place upgrades