AOI inspection of tomorrow

The future of AI in AOI:

Smarter, faster AOI inspections within SMT lines

Artificial Intelligence is reshaping AOI with advanced image recognition, boosting speed and accuracy like never before. Keep reading to learn how AI is making inspections smarter and improving performance in SMT production

The impact of artificial intelligence in AOI inspection

AI in AOI: A game-changer for smarter SMT inspections

AI is rapidly transforming how manufacturers approach AOI. OEM and EMS manufacturers alike are racing to integrate AI into their processes, aiming to take automation in SMT lines to the next level.

With its ability to learn and adapt, AI extends the speed and precision of machines into complex tasks that require human-like judgment, making AOI smarter and more reliable.

AI's powerful image recognition skills, already used in fields like medical diagnostics and autonomous driving, are a perfect match for industrial quality control, especially AOI.

Traditionally, AOI relied heavily on the AOI expert judgment for setup, product introduction, and inspection of potential defects. But with AI, the process is becoming more automated, accurate, and efficient.

Now, AI-driven AOI systems can automatically match components to the right library using deep learning, speeding up setup and improving accuracy. It can even measure 3D components that aren’t in existing libraries, making inspections faster and smarter than ever before.

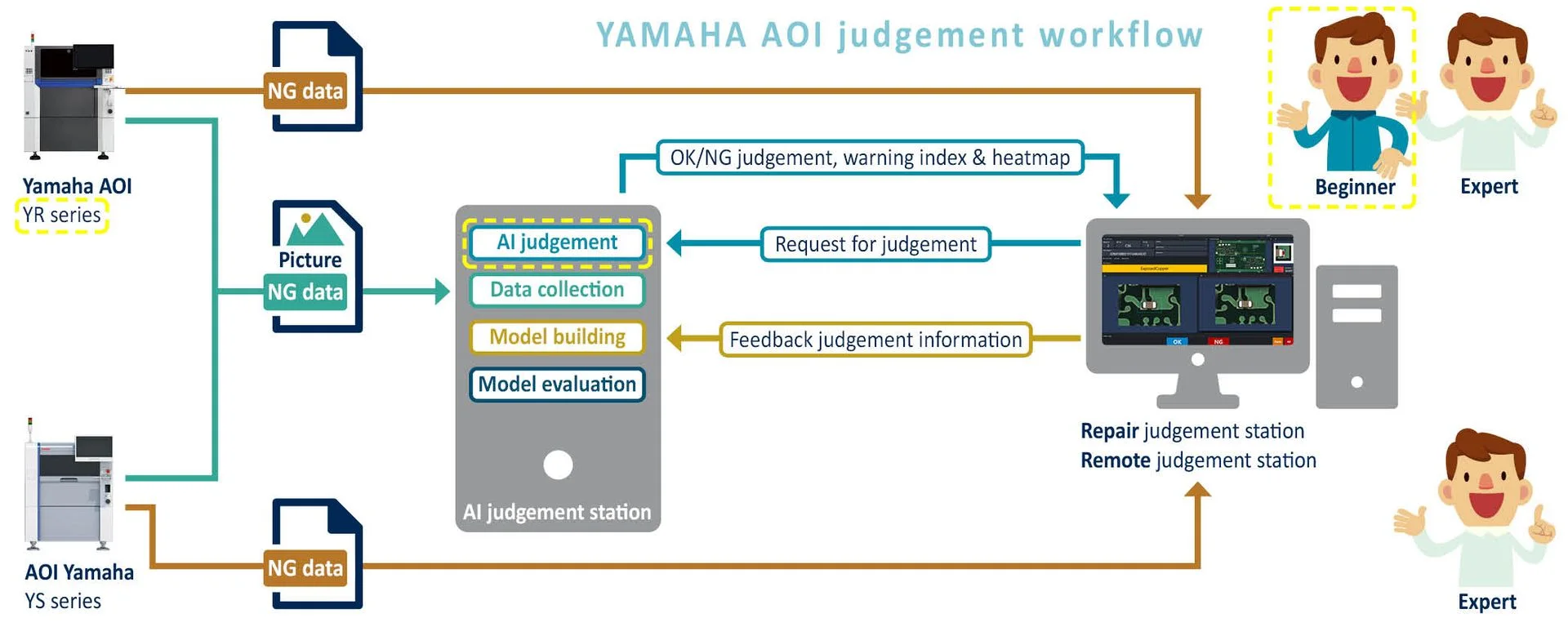

AOI inspection workflow

AI-enhanced judgement: Boosts accuracy & productivity on SMT lines

AI has already streamlined library management, but it’s now stepping up to tackle the critical task of improving inspection accuracy.

Traditionally, classifying defects - whether real, false positives, or false negatives - relies heavily on human judgment, which can slow down the process and introduce variability.

While obvious defects like missing components or major soldering issues are easy to catch, others are more subtle, making consistent classification a challenge.

Relying solely on human operators can lead to inconsistencies based on individual experience or judgment. This slows down inspections and can result in overlooked defects or unnecessary rework from overly strict assessments.

By integrating AI into this 'secondary judgement' process, manufacturers can minimize human error, boost inspection speed, and ensure greater consistency.

With AI-assisted systems, detected defects are shared with both human operators and the AI software. As operators make judgments, these inputs are fed back into the AI, allowing it to learn and fine-tune its own decision-making. Over time, the AI can match the performance of skilled inspectors, making quicker, more accurate judgments and freeing up operators to focus on higher-level tasks.

This AI-powered approach not only increases productivity by reducing false positives and missed defects but also helps maintain stable quality throughout production, ensuring that every unit meets the required standards.

Smarter AOI workflows

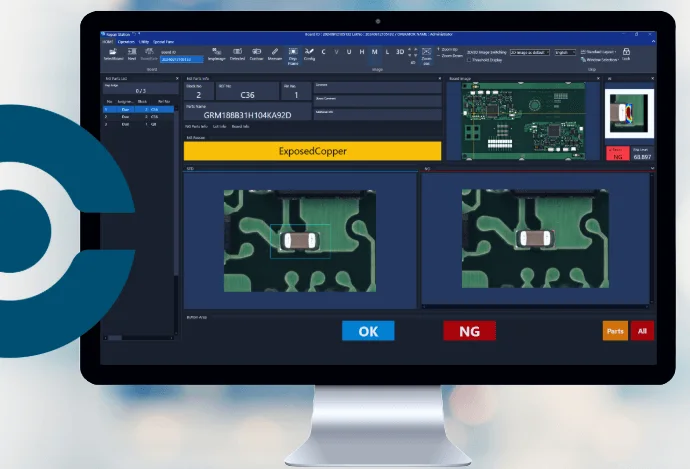

Confidence index: How AI brings clarity to AOI decisions

Yamaha SMT’s AI judgement software for AOI doesn’t just make decisions — it explains them. By providing operators with detailed feedback, including images, tables, and a confidence index (figure 2), it gives full transparency into its Good / NoGood calls.

For soldering defects like bridges or contamination, the system offers a heatmap and an anomaly index to highlight problem areas. When it comes to defects like character recognition, it uses a matching ratio to indicate how confident it is in its assessment.

The software also tracks its own performance, measuring how well it detects anomalies and suppresses false positives.

With ongoing data collection and analysis - like noise reduction and custom AI model optimization - users can fine-tune the system over time.

This AI-powered tool empowers operators to manage quality control without needing expert oversight, guiding repairs with precision and ensuring consistently high standards.

Figure 2. Inspection analysis includes images and the calculated anomaly index, shown, assist secondary judgement and help to guide repair as necessary.

AOI inspection of tomorrow

From assistance to full automation: The future of AI in AOI

The next leap for AOI is moving from AI-assisted judgement to fully autonomous inspections that match the expertise of the best human operators.

Yamaha’s AI Judgement software is already equipped to seamlessly connect with remote repair stations and inline AOI systems, sharing its results to continuously enhance inspection accuracy. By automating secondary judgement, inline AOI systems can run independently, maintaining high accuracy with minimal false positives or negatives, reducing defects, and preventing unnecessary rework.

AI is transforming every step of the AOI process, from speeding up library creation to automatically generating missing component data. With its advanced image classification capabilities, AI is already making an impact on the production line, assisting operators in making faster, more accurate decisions.

Looking ahead, the path is clear: AI will drive end-to-end automation, continually learning to improve quality assurance and boost productivity across the entire SMT process.

The future of AI in AOI: Smarter, faster AOI inspections within SMT lines