YAMAHA YRi-V vision Yamaha AOI inspection

AOI inspection with YAMAHA YRi-V vision

New state of the art 2D and 3D YAMAHA AOI offering new features that will impact both usability and output quality with new interface with easy program creation.

Using 3D AOI inspection imaging function you get higher reliably as it detects floating components that a 2D inspection can miss.

YAMAHA YRi-V AOI inspection unit includes many smart features e.g. automatic parameter settings cuts data-tuning time by 50%, automatic component AI library matching.

- 2D + 3D Inspection | AOI machine: 3 functions in 1 machine

About Yamaha AOI; Yamaha YRi-V vision

Automated Optical Inspection at is best with YRi-V

-

2D inspection

The 2D inspections are powered by a 12 MP camera with 12 µm resolution, paired with a telecentric lens to ensure accurate image capture without distortion. The system utilizes five inspection methods to deliver reliable defect detection: brightness, infrared, color, shape, coaxial lighting

For applications demanding higher precision, an optional 25 MP camera is available, supporting 7 µm or 5 µm lens resolutions.

-

3D inspection (option)

The 3-dimensional inspections are performed with either a 8 (or 4) way projector that performs 3D inspections that e.g. detects SMD heights up to 25 mm, slope gradient and direction

-

3D Blue Laser for transparent components (options)

-

4 direction (option)

4-way angular camera with 20 megapixel resolution

-

Single or dual lane system

-

Applicable PCB:

- L 610 x W 610 mm (maximum)

- L 50 x W 50 mm (minimum)

- L 750 mm longer PCB (Option)

- Machine size: L 1.252 mm x W 1.497 mm x H 1.614 mm

- Machine weigh: 1.480 kg

-

Speed! Industries fastest inspection speed

- 60% faster with 12 micrometer lens

- 100% faster with 7 micrometer lens

-

New 5 micrometer model - super high resolution 8 way projection. Double 3D accuracy.

- Detects scratches and cracks on mirrored surfaces new coaxial lighting.

-

Foreign material detection

-

YSUP Yamaha’s Intelligent Factory Solutions:

- IPro database inspection analysis

- Dashboard live monitoring

- Quality Assurance (QA)

- Mobile judge

-

Larger boards up to 750 mm long.

-

AI library matching

-

CAD + CAM conversion with Gerber support

-

THT / trough hole technology inspection algorithms

For more information download the flyer below or watch the video.

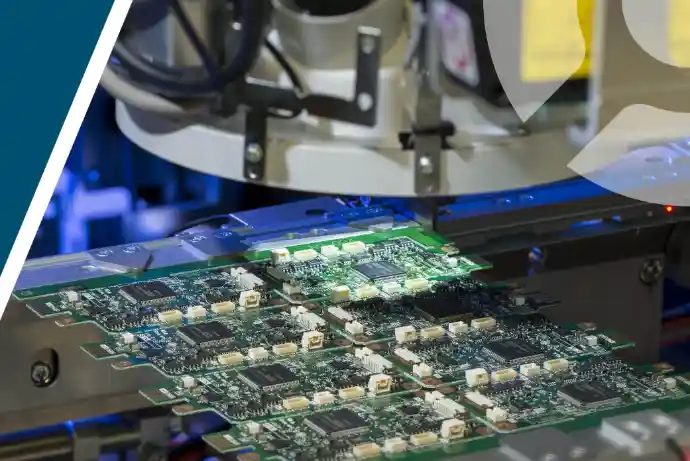

Inspection camera inside the YAMAHA AOI

Download YAMAHA AOI brochure

Download datasheet on YRi-V | YRi-V spec sheet to download as a PDF file with more information on the YAMAHA YRi-V inspection unit. Get all AOI specifications on the YAMAHA inspection machine.

YAMAHA AOI video presenting YRi-V

Automated optical inspection with Yamaha YRi-V | Get a thoroughly introduction to the YAMAHA AOI; YRi-V with an informative AOI inspection functions this AOI performs.

Yamaha AOI price or more YRi-V info?

More info, a price or guidance? AOI Inspection equipment and inline SMT inspection machinery that is what we excel in. Do you have any questions about AOI SMT inspection? Please contact us.