Tired of SMT line stoppages?

Here is how to keep production running

Reducing unplanned stoppages is key to higher productivity in surface-mount manufacturing.

Smarter equipment makes that possible

When component pick & place machines monitor their own performance & detect anomalies in real time, production keeps running - even when small issues arise. Instead of sudden downtime, engineers can handle faults at the right time, preventing minor hiccups from becoming costly stoppages.

The result? Fewer disruptions, higher OEE, and a production line that runs longer and more efficiently.

Smarter solutions for fewer SMT line stoppages

Keeping production flowing smoothly means anticipating and solving issues before they lead to downtime. Both software and hardware upgrades play a key role in this, helping SMT equipment adapt in real time and stay productive.

Take high-speed surface mounters, for example. These machines already have built-in inspection cameras and motion controls - so adding new self-check features can often be as simple as a software update.

However, some issues may require additional hardware, like extra sensors or actuators, to detect and resolve problems before they escalate.

One of the most common SMT production headaches is nozzle blockages. Nozzles are constantly being loaded and unloaded, stored in a dedicated nozzle station, and assigned fixed positions during setup. If a nozzle starts performing poorly, it can disrupt production.

With Yamaha’s new 'Nozzles Free Layout' software, that problem is solved.

Instead of keeping nozzles in fixed positions, the machine identifies them individually using 2D codes. This means the system can automatically swap out a faulty nozzle with another of the same type - without stopping production. Operators can also track nozzle performance more accurately and avoid errors when reloading after cleaning or maintenance.

This is a great example of how a simple software change can make SMT lines more resilient.

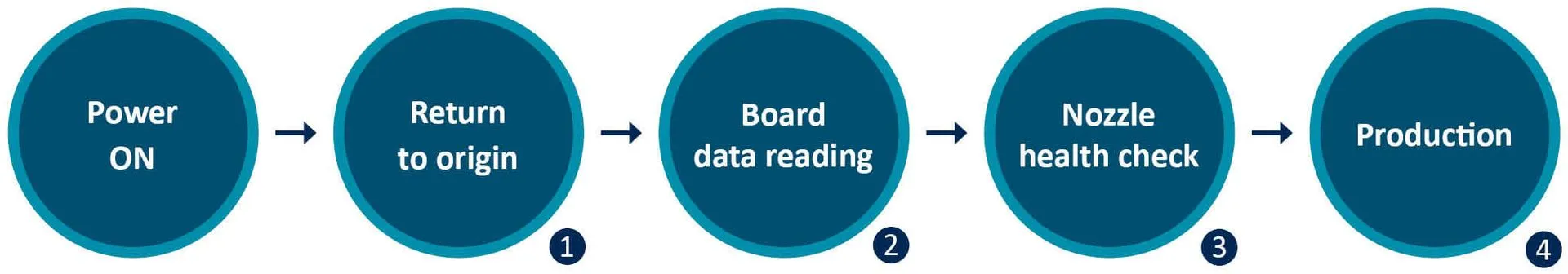

Nozzle Free Layout workflow chart above

- Nozzle registration: The system registers each nozzle’s position on the station.

- Head allocation: Combination of head and nozzle used for board data is linked to the station

- Spare nozzle management: Unused nozzles act as spares and can replace stained or faulty nozzles to maintain production.

- Nozzle monitoring: Nozzles are Individually monitored for pick-up count and error rate, improving maintenance and performance tracking.

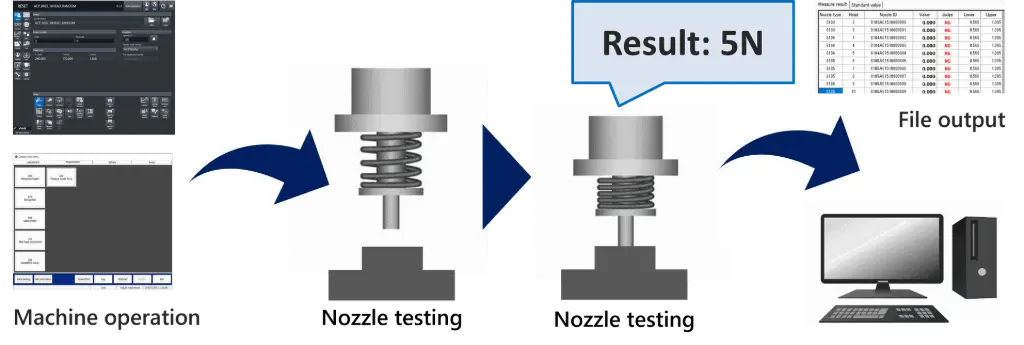

For other upgrades, new hardware is the key. Yamaha’s nozzle tip force measurement system is a prime example. This upgrade, which can be installed on new or existing machines, adds a load-cell assembly that precisely measures the nozzle’s placement force - down to 0.1 Newton resolution.

If a nozzle is applying too much or too little pressure, it could indicate debris interference or a spring issue. By catching these problems early, manufacturers can avoid placement defects and costly rework.

The system also makes troubleshooting easier, providing real-time calibration and guiding operators through the process with clear, menu-driven instructions.

Nozzle tip-force measurement with load cell hardware.

These types of smart, proactive upgrades - whether software-based or hardware-enabled - help SMT teams reduce stoppages, improve efficiency, and keep production flowing.

Easy-to-add hardware upgrade

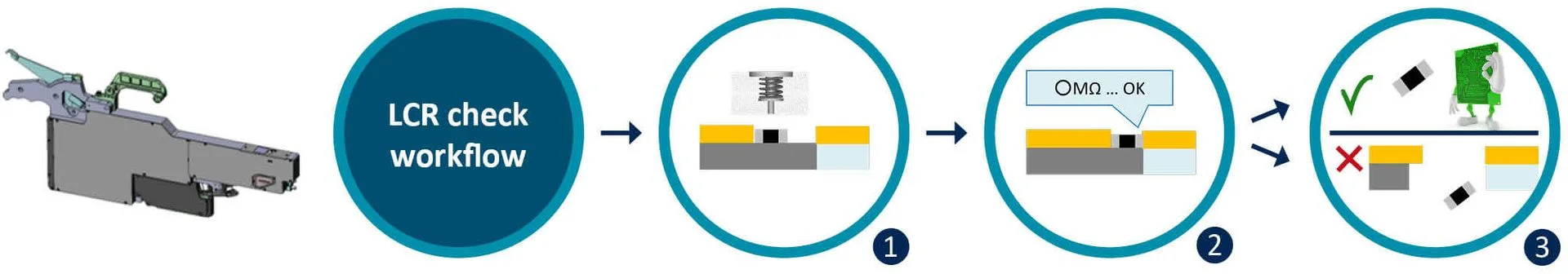

One easy way to boost your mounter’s capabilities without interrupting production is by adding Yamaha’s LCR unit.

This simple hardware upgrade fits seamlessly into your existing setup with no need for complex modifications. The LCR unit, which is designed in a standard feeder format, integrates a digital multimeter that measures components automatically before they hit the board.

It checks the value of each part, whether it's inductive, capacitive, or resistive, ensuring the component matches the reel label.

This can be especially useful when changing reels, as it ensures that every component meets the required specifications. If there’s any discrepancy, defective parts are immediately rejected.

LCR unit workflow: Simple, fast and automatic component checking

-

Component is placed in the LCR unit

-

Measurement and verification take place

-

Approved parts are placed on the board, while defective parts are automatically discarded to feeder cart bin box.

With the LCR unit, you’ll catch potential issues - like feeder or reel errors - before placement, helping you increase first-pass yield and minimize rework. It only takes up two standard 8 mm feeder slots, so it’s easy to install on any Yamaha mounter without halting production.

Plus, no special software is needed. It’s simply plug-and-play.

This quick upgrade boosts quality control and is particularly valuable when working with low-cost components or industries where traceability is critical, such as automotive, medical, or aerospace manufacturing.

Uninterrupted production - Smart tools for keeping production running

Yamaha offers several software upgrades that can keep your production line running smoothly without interruptions. These upgrades are simple to implement and make a big difference in SMT line productivity.

One upgrade is the Automatic Multi-Vendor Support, which addresses issues that arise when different suppliers provide the same component.

When components are sourced from multiple vendors, they may have slight differences - such as how they’re oriented in the tape pockets or variations in feeder pitch - that could cause the machine to mark a component error.

With this upgrade, the mounter’s database adapts to these differences, avoiding unnecessary production stoppages.

The Pick-up Evaluation feature uses the mounter’s side-view camera (a standard feature) to automatically check the component’s orientation after pick-up. This helps verify key parameters like pick-up height, X-Y movement and vision recognition.

By streamlining these checks, this option reduces setup times, making new product introductions faster and more efficient. It also optimizes component information during production, cutting decision-making time to just a few seconds.

Another time-saver is Auto-Teaching, which allows operators to fine-tune library & Gerber data directly on the mounter. This helps avoid building test boards to check component alignment and orientation before production. It’s a quick way to ensure everything is set up correctly, speeding up the whole process.

Yamaha also offers an Unused Parts Feeder Removal tool, a real lifesaver during product changeovers. When the new product needs extra feeders but the mounter is already at capacity, manually checking for unused feeders can be tedious and time-consuming.

This software automates the process, quickly identifying which feeders can be swapped out, so you can complete changeovers faster and get production back on track.

For heavier / long jobs, Yamaha’s Large-Board Conveyor Upgrade provides the solution. With an enhanced conveyor system capable of handling boards up to 10 kg and 10 mm thick, this upgrade is perfect for large, heavy components like those used in extra-large LED-lighting assemblies.

Compatible with the YRM20 single beam mounter, the conveyor can handle boards up to 1.5 meters long, making it ideal for industries like automotive or heavy electronics.

These software and hardware upgrades are designed to enhance productivity, minimize downtime, and make changeovers easier, all while keeping your mounters running smoothly and efficiently.

Final thoughts: keep production moving smoothly

By incorporating optional hardware and software upgrades, your SMT assembly equipment gains the ability to autonomously detect, diagnose, and respond to potential issues before they cause downtime.

These upgrades add smart resilience to your machines, helping you prevent small issues from snowballing into costly stoppages.

This not only boosts productivity but also allows your operators to focus on the more complex problems that truly need their expertise - keeping your production lines running without interruptions.

Tired of SMT line stoppages? Here is how to keep production running