Yamaha SMT nozzles for SMD mounting

Accurate SMD placement in the Pick & Place machine, is handled with immaculate precision of the modular mounting head that provide exact placement position and height, and the SMT nozzles handles efficient component pick-up and placement of the components.

Yamaha SMT nozzles health-care - smart, automated & reliable

Yamaha nozzle health-care process

A) Start production

Once production is underway, Yamaha’s intelligent nozzle health-care process kicks in – working quietly in the background to keep your nozzles in top shape.

B) Automatic inspection & cleaning

The system performs a series of checks to ensure each nozzle delivers optimal placement accuracy:

-

Checks nozzle for solder debris & chipping by sideview camera

-

Checks correct nozzle eccentricity by camera below nozzle

-

Checks the nozzle feathers buffing ability ensuring free movement

- Nozzle cleaning station that blows high pressure air through nozzle shaft & sideways

The nozzle health-care check is easily scheduled by the operator. Once set, the Yamaha Pick & Place machine automatically performs the inspection and cleaning cycles according to the defined schedule - ensuring ongoing nozzle performance without added workload.

C) Nozzle pass or fail

Nozzles that pass the test go back into operation.

Nozzles that don’t? In the latest Yamaha YR series models – including YRM20 and YRM20DL – failed nozzles are automatically stored and replaced with fresh spares from the nozzle station. No manual intervention needed.

Easy nozzle washing

When deeper cleaning is needed, simply detach the nozzle holder with one touch and transfer it to an automatic nozzle washer. Clean, simple & efficient.

Low impact nozzles for low impact SMT mounting

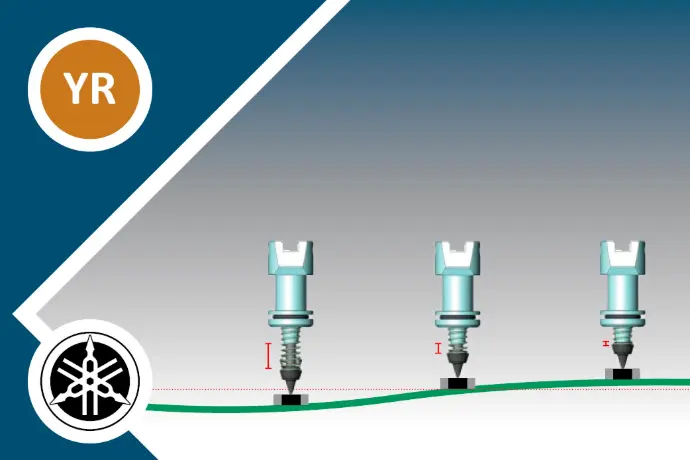

As the Yamaha Pick & Place machine measures the board warpage, the component mounting height is aligned according to each PCB to prevent the component either to overstress due to over-pressing or not to reach the board properly.

The Yamaha YR series mounters also offers a low static nozzle range; Low impact nozzles with unique ID and low static load / mount spring , that reduce stress on the smallest components such as 008004" (0201 mm) and improve the ability to perform placement of the super-tiny SMDs side by side in narrow spaces.

Need Yamaha SMT nozzles?

We offer SMT nozzles as a single nozzle or in nozzle sets. Contact us for more nozzle info.

Yamaha SMT nozzle cleaning station

The nozzle cleaning is an automatic cleaning feature, that cleans the nozzles by blowing high-pressure air through the nozzle and spline. This keeps the nozzles clean for extended periods.

The SMT nozzle cleaning station is placed just behind the nozzle station, and is available on Yamaha YR and YS series.

Yamaha SMT nozzle station

The SMT nozzles are safely stored in the nozzle station that is placed inside the Pick & Place machine, in fast access range for the mounting head.

Yamaha SMT nozzle station is found the Yamaha YR and YS series.