Next-gen entry-level screen printing - the Yamaha YRP10e explained

More performance - Less cost - Smarter printing

In today’s SMT landscape, demands are shifting. Whether you’re an OEM or EMS provider in Scandinavia or the Baltic region, the expectation is clear: do more, with less. Less footprint, less downtime, less cost - and all while handling complex boards, smaller components and faster changeovers.

That's where Yamaha's YRP10e screen printer steps in. It brings features you'd expect from high-end machines down to a more accessible level - without cutting corners on quality or speed.

Why smart screen printing matters in modern SMT lines

Smart homes, electric vehicles, factory automation - the future is packed with connected devices. These product trends open new business opportunities, but only if you can deliver PCBA fast, reliably and cost-efficiently.

To stay competitive, SMT lines need smarter machines. That’s why Yamaha built the YRP10e using proven technology from their high-end equipment - e.g. including the solid chassis from the YRP screen printer, which helps reduce vibration and keep print quality stable.

Also, they added a smart set of features tailored to today’s production demands - focused on entry-level users who need reliable performance without complexity.

The result? A screen printer that combines high-end capability with entry-level ease at a very competitive price.

High-speed screen printing with a three-stage conveyor

Let’s talk cycle time. The YRP10e achieves a 6-second core cycle time, which puts it close to some of todays fastest printers made for high-volume production.

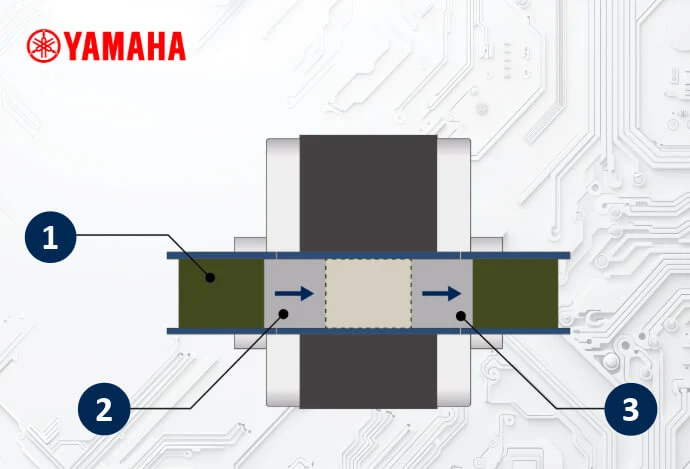

A smart three-stage conveyor system that keeps PCBs flowing smoothly - without slowdowns or wasted time.

Here’s how it works:

- stage - infeed / standby for print

As soon as a PCB arrives, it’s held in a standby position - ready to be moved to the print stage the moment it’s available. - stage - printing stage

Because the standby PCB is already inside the machine and just a short distance away, it takes minimal time to transfer it to the print stage. - stage - outfeed / carry-out standby

As soon as a PCB finishes printing and moves to the carry-out position, the system immediately brings in the next PCB from standby.

Caption: The three-stage conveyor keeps multiple PCBs inside the machine, allowing one to be printed, one waiting, and one exiting - all at the same time.

Faster setup and less human error in SMT printing

Manual stencil alignment works - if your operator is experienced. But not everyone is.

The YRP10e offers a universal stencil holder as an option. One-touch setup handles standard stencil sizes automatically.

You remove guesswork, reduce errors and shorten training time. Everyone can get the best result - every time.

Accurate print alignment from the first board

One of the standout upgrades: graphic visual alignment. Forget wasting time and boards on print trials after each changeover.

This system helps get it right from the first print, making it ideal for low to mid-volume production with frequent changeovers.

Smart features that boost print quality and output

- Stopperless transport adapted from Yamaha’s AOI systems ensures smooth and fast board entry (up to 600 mm/s) eliminating position errors.

- Vacuum jig for the stencil eliminates print variation caused by squeegee direction.

- Edge-clamp pressure control via software makes fine adjustments easier and consistent.

- Overprinting helps after long stops or stencil changes - delivering solid results from the very first print.

Better solder paste performance with Yamaha’s 3SR Squeegee

Yamaha’s 3SR stepped squeegee may look simple - but it delivers powerful improvements where it counts:

- Smoother paste rolling

- 5% better aperture fill

- Longer stencil life

- Eliminate solder flakes

These gains come from a redesigned blade shape, improved pushing power, and optimized steel hardness.

The result? Less wear on the blade, better protection of your stencil, and consistently high-quality prints over time.

Pro-level software in an entry-level printer

Software is where the YRP10e really shines for its price point. Features normally seen in premium printers are now included as standard:

- Stencil and paste life checks

- 2D barcode scan to avoid using worn-out stencils

- Paste roll width monitoring every two strokes

- Squeegee and paste validation as per board file

These built-in checks help keep your print process consistent - and protect you from costly rework.

The right fit: What the YRP10e does - and doesn’t - include

Is the YRP10e fully automated like Yamaha’s premium models? No - and that’s the point.

It’s designed for companies that don’t need all the bells and whistles but still want reliability, speed and flexibility.

For example:

- No automated stencil loading (that’s still for high-volume environments)

- No automatic paste replenishment, but it alerts operators before problems arise

You get what you need - and only what you need.

YRP10e entry-level doesn’t mean basic

At CORE-emt, we know that cost pressure is real, but so is the need for future-ready SMT lines. Yamaha’s YRP10e proves that entry-level doesn’t mean basic.

It’s a thoughtful, capable solution that’s perfect for companies ready to scale smart - and spend smart.

If you're working in SMT production in the Nordic or Baltic region and want to get more from your printing process, the YRP10e might be just what you're looking for.

Next-gen entry-level screen printing - the Yamaha YRP10e explained