YAMAHA SMT machine to machine collaboration

YAMAHA SMT M2M collaboration linking the SMT line

YAMAHA SMT machine to machine collaboration

Benefit by between machines collaboration to access quality assurance due to intelligent machine to machine collaboration tools in the YAMAHA YsUP software package offers.

The YAMAHA YsUP Machine to Machine software is a part of YAMAHA SMT's new software platform.

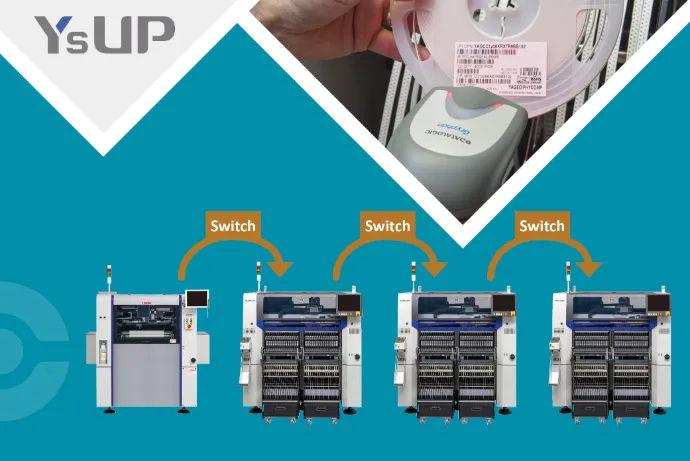

Automatic job change-over

Setup to a new job in one swift motion with automatic change-over for tooling, programs, setup and conveyor width with the APOC (Auto Program Change-Over) function.

Also available is the SEMI SMT-ELS's Immediate product change. Get in touch for more information.

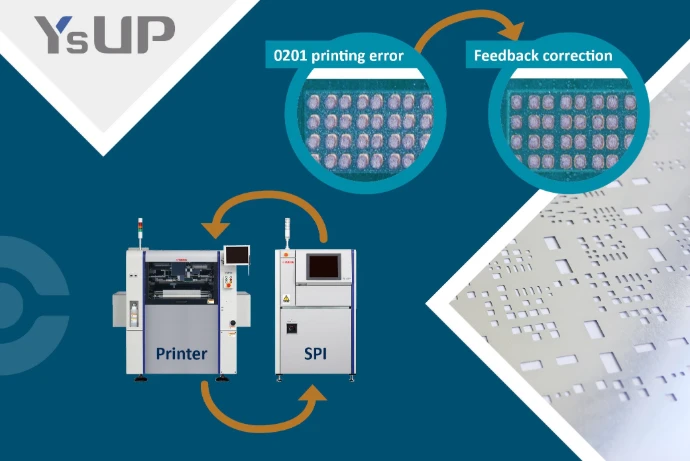

Feedback & correction

M2M Screen Printer ↔ SPI

Even the smallest solder print displacements errors can create huge challenges further down the PCB assembly line. The Solder Paste Inspection SPI results can be fed back to the printer to automatically adjust to correct solder print placements.

Also, the SPI unit can request stencil cleaning operation on the Screen Printer when needed.

On the picture you see a 008004" (0201 mm) printing displacements error

before and after correction by SPI feedback to Screen Printer.

Pass or fail judgement on mobile

M2M Mounter ↔ AOI

Make 'pass or fail' judgement based on AOI inspection to 'pass or fail' potential issues found by on your PCB's on the spot.

All potential issues found by AOI inspection are sent to the operator’s mobile device in real time. Making it possible to make 'pass or fail' decisions while e.g., setting up feeders for a new job or simply fetching a cup of coffee.

Feedback & correction

M2M Mounter ↔ AOI

The Quality Assurance tool is a smart AOI function, that pinpoints exactly the head on the mounter placing the component that is shifted or in another way triggered an issue result.

The Quality Assurance tool software shows the operator the NG issue message, and enable him to check actual images from the Pick & Place unit of:

- pick-up state

- pick-up position

- mounting position

To pinpoint the issue origin & gain the knowledge to fix the issue in real-time.

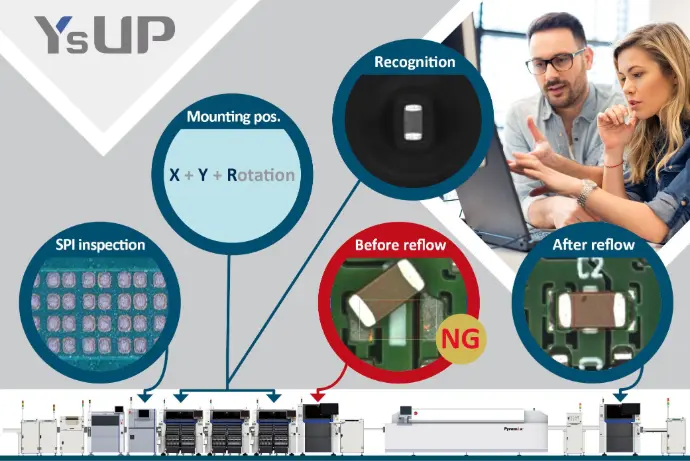

Simultaneously display the same

PCB point in each process

Process collaboration M2M

Swiftly pinpoint SMT process where an NG issue occur, by seeing images of the component status throughout the production simultaneously.

Images that display the status in the following processes:

- SPI solder paste

- P&P mounting position + component recognition

- AOI before reflow + after reflow

Pinpointing the NG point - to correct the issue right away - that is the smart and efficient way to perform quality improvement inline during production.

M2M workflow video

See the video presentation of the YAMAHA machine to machine workflow between the YAMAHA SMT equipment and the YAMAHA M2M software.

Questions about the YsUP Machine2Machine collaboration package

We assist you personally with prices and more information