YAMAHA press release - new product launch

Yamaha Motor Europe Robotics SMT Section announced today that the new YRM20DL surface mounter* that is launched on April 3, 2023.

The YRM20DL is a premium high-efficiency modular that achieves improved actual and per-unit-area productivity with a newly developed high-rigidity dual-lane conveyor by further reducing transport losses etc. YRM20DL is built on the basic performance of the company’s flagship high-speed, high-accuracy, high-versatility, universal mounter YRM20.

YRM20DL supports a maximum PCB width of up to 330 mm where the same width PCB is being conveyed at the front and rear while in dual-lane production mode. In the case of parallel mounting, the front and rear heads can operate without any interference up to a maximum PCB length of 380 mm, enabling high-efficiency mounting without loss.

Furthermore, the basic performance of the unit has been further enhanced to achieve an overwhelming productivity of 120.000 CPH** (under optimal conditions)***, the world’s highest level of speed in its class, along with a higher-accuracy placement of ±15µm (Cpk≥1.0) through the revision of the layout such as bringing the mounted components pick-up area and the mounting area closer together, optimizing the main spindle motion control, improving the rigidity of the conveyor and the corrective functionality etc.

By taking advantage of the Yamaha Motor’s strengths as a full-lineup manufacturer of mounting equipment, including surface mounters, printers, dispensers, and inspection systems. The company promotes the Intelligent Factory system, which comprehensively realizes higher efficiency in the mounting process through smooth and advanced inter-equipment cooperation without black boxes.

* Surface mounters: Production equipment designed to mount various electronic components onto PCB's (Printed Circuit Boards), which are then incorporated into electronic products.

** CPH (Chips Per Hour):

Total number of chips that can be mounted per hour (unit time). Indicates processing capacity under various conditions.

*** Comparative mounting capacity (CPH) under optimal conditions for surface mounters in the 2-Beam, 2-Head Class. Yamaha Motor survey, February 1st, 2023.

Market background and

product outline

In addition to the rapid electrification of powertrains for in-vehicle electronics, the miniaturization, high-densification, high functionality, and diversification, as well as shortened product cycles have increasingly accelerated for a variety of products such as appliances, personal computers, and mobile telephones.

In response to this, the miniaturization of components have also progressed, and higher-performance, higher-efficiency equipment with greater flexibility and efficiency has been introduced, promoting a dramatic increase in production capacity at manufacturing sites.

However, along with improvements of these throughputs, the ratio of fixed-value losses that do not generate value, such as transportation time to production time, have also come into focus.

Premium dual lane YAMAHA modular YRM20DL

Premium dual lane YAMAHA modular YRM20DL Yamaha Motor has therefore newly developed the YRM20DL, a dual lane version of the YRM20 which is the latest flagship mounter to adopt the new generation platform. The unit supports various dual-lane production methods, such as transporting two PCBs of the same type by parallel mounting, transporting two PCBs of different types, and alternate mounting, making it possible to select and operate the optimal production system for each product PCB type.

As a result, fixed-value losses such as transport losses can be greatly reduced in a wide variety of SMT production lines, from high-speed mass production to high-mix low-volume production, along with improved actual productivity and per-unit-area productivity.

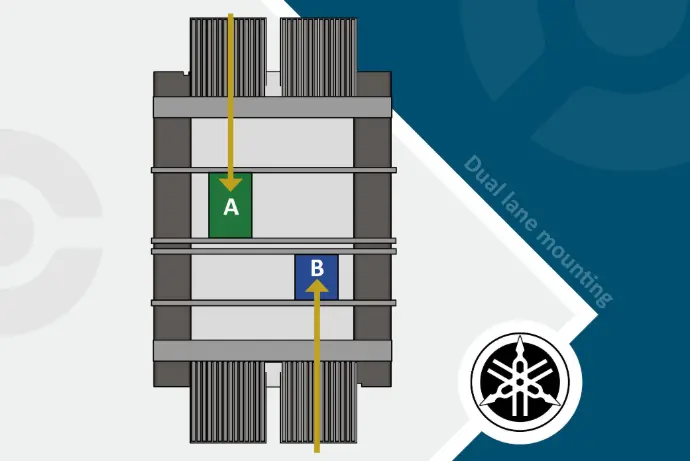

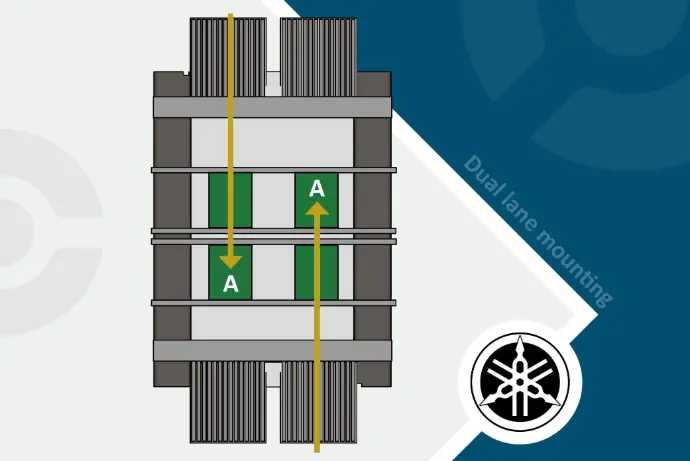

Example: Dual lane mounting possibilities

Arrows indicate movement of the head

Same type of PCB's by parallel dual lane mounting.

Different types of PCB's performed by dual lane mounting.

Supporting mounting innovation --NEW --

Preparation work (transportation, fixing, etc.) for the next PCB can be performed in 1st lane, while the 2nd lane still mounts. Allowing the head from the 1st lane to immediately move to mounting action on the 2nd line, reducing time loss from waiting / standby.

YAMAHA dual-lane modular YRM20DL features

Achieves higher speed & accuracy by improved basic performance

The newly designed RM head for the YAMAHA YRM20DL modular

The newly designed RM head for the YAMAHA YRM20DL modularBy revising the dynamic layout, the unit has achieved the world's highest level of 120,000 CPH in its class (under company optimum conditions) realizing overwhelming productivity.

This has been achieved by way of minimizing the movement distance by bringing the pickup and mounting areas closer to each of the two heads, and further optimizing the overall spindle motion control.

High-accuracy mounting of ±15 μm (Cpk≧1.0) is achieved by increasing the rigidity with the newly developed conveyor and improving the correction function.

The RM head / HM head supports 008004" (0.25 x 0.125 mm) sized ultra-small chip component mounting and narrow adjacent mounting.

Adoption of a newly developed dual-lane conveyor

that reduces transport loss and improves per-unit-area productivity

The newly developed high-rigidity dual-lane conveyor supports a maximum PCB width of up to 330 mm where the same width PCB is being conveyed at the front and rear while in dual-lane production mode.

An ultra-high-speed rotary RM head that employs overdrive motion (mutual head insertion) allows the front and rear heads to operate without any interference up to a maximum PCB length of 380 mm, enabling highly efficient mounting without head standby loss.

In single-lane production, which uses only one of the two lanes, it is possible to transport PCBs up to a maximum 810 x 610 mm (length x width), with a transportable weight of 3 kg, and a maximum PCB thickness of up to 6.5 mm.

This new model is also compatible with a wide range of extra-large-sized PCB's, jig conveyance, etc., including for automotive products, industrial, medical, power devices, and LED lighting.

Overdrive motion within the YRM20DL

Overdrive motion within the YRM20DLOther Yamaha YRM20DL key features

Mounting head can be selected from 3 types

- Ultra-high-speed rotary RM head with overdrive motion

- In-line HM head that combines high speed and high versatility with "1 head solution" that can handle ultra-small chip components to larger components with one type of head

- In-line type FM head capable of handling tall and odd-shaped components

More about the >> Yamaha mounting head types <<

Supports various labor-saving functions

- Auto-loading feeder that can easily replenish tape components at any time without the need to stop production

- eATS30, a non-stop tray feeder that can supply tray components in units of pallets/magazines without the need to stop production

- Non-stop loading/unloading feeder cart that enables setup work for feeder carriages replacement without the need to stop production on one lane

- Automatic exchange of push-up pins, greatly reducing workloads when changing products

Integrity and ease of maintenance

- Nozzle ID management that enables maintenance optimization according to the number of accumulated shots

- Self-diagnostic and self-recovery functions maintain a clean state, allowing continued high-quality production nozzle health care/feeder maintenance warnings

YM20DL basic specifications

RM head Super high-speed rotary | HM head High-speed general-purpose in-line | FM head Flexible head for odd shaped chips | |

| Nozzles, per 1 head unit | 18 | 10 | 5 |

| Applicable components | 0201mm to W12xL12 mm Height 6.5 mm or less | 0201 mm to W55xL100 mm Height 15 mm or less | 03015 mm to W55xL100 mm Height 30 mm or less |

| Mounting capability (under optimum conditions) | 120.000 CPH (In high production mode) | 100.000 CPH (In high production mode) | 2-beam: 35.000 CPH 1-beam: 17.500 CPH |

| Mounting accuracy Cpk ≥ 1.0 | ±15 μm (high-accuracy mode) | ±15 μm (high-accuracy mode) | ±35μm |

| Number of component types | Feeder cart: Max. 128 types = 32 feeders × 4 (conversion for 8 mm tape feeder) Fixed plate: Max. 128 types (conversion for 8 mm tape feeder) Trays: 60 types (maximum when equipped with eATS30 x 2) | Feeder cart: Max. 128 types = 32 feeders × 4 (conversion for 8 mm tape feeder) Fixed plate: Max. 128 types (conversion for 8 mm tape feeder) Trays: 60 types (maximum when equipped with eATS30 x 2) | Feeder cart: Max. 128 types = 32 feeders × 4 (conversion for 8 mm tape feeder) Fixed plate: Max. 128 types (conversion for 8 mm tape feeder) Trays: 60 types (maximum when equipped with eATS30 x 2) |

| PCB dimensions | Dual lane use: W50 x L50 mm to W330 x L810 mm Single lane use: W50 x L50 mm to W610 x L810 mm | Dual lane use: W50 x L50 mm to W330 x L810 mm Single lane use: W50 x L50 mm to W610 x L810 mm | Dual lane use: W50 x L50 mm to W330 x L810 mm Single lane use: W50 x L50 mm to W610 x L810 mm |

| Power supply | 3-phase AC 200/208/220/240/380/400/416 V ±10% 50/60 Hz | 3-phase AC 200/208/220/240/380/400/416 V ±10% 50/60 Hz | 3-phase AC 200/208/220/240/380/400/416 V ±10% 50/60 Hz |

| Air supply source | 0.45 MPa or more, in clean, dry state | 0.45 MPa or more, in clean, dry state | 0.45 MPa or more, in clean, dry state |

| External dimensions (excluding projections) | L 1,374 x W 2,102 x H 1,445 mm | L 1,374 x W 2,102 x H 1,445 mm | L 1,374 x W 2,102 x H 1,445 mm |

| Weight | Approx. 2.550 kg (main unit only) | Approx. 2.550 kg (main unit only) | Approx. 2.550 kg (main unit only) |

YAMAHA SMT launches premium dual-lane modular YRM20DL